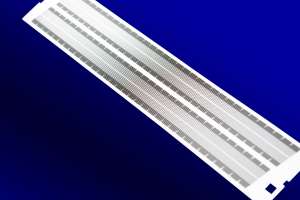

UV Lasers

Precision, Repeatability, and Tight Tolerances

How the UV Laser Works

The shorter wavelength ultraviolet (UV) lasers mean a shorter, more focused positioning laser, resulting in a higher precision process. The material is cut without burs and possible pressure from the cutting tool. The shorter wavelength also causes no damage and no change to the mechanical or electrical properties of the workpiece, making it ideal for nonmetal insulating materials such as Kapton, PTFE, and Nomex paper.

In addition to the low workpiece temperature, the high-energy photons that exist in ultraviolet light allow the UV laser to be used with non-metallic and other various materials. Source from stylecnc.com

Benefits of using Thin Metal Parts for your UV Laser needs

- Rapid prototyping

- In-house engineering

- 20um beam

- Insulation thickness: 0.0005”-.010”

- Positioning Accuracy - +/-25um

- Repeatability +/-2un

- Excellent beam quality and pulse stability as well as precise power control.

- Aspect ratio- (thickness vs. through-hole features)

- Tolerance can be held as low as +/- 13µm (part shape dependent)

- Wide range of materials – metallic and non-metallic

- Post-process cleaning and inspection

- Microview Metrology Vision System

UV Laser Materials

The UV laser cuts metals, non-metallic insulating, and other lamination materials. The materials include but are not limited to mylar, Kapton, PCB materials, and Nomex paper.

When precision is essential for cutting insulating material, especially for electric motor lamination and the medical, aerospace, and automotive industries, Thin Metal Parts is there to make sure you receive the precision you need.

Thin Metal Parts is the industry leader in a wide range of metal fabrication techniques, including mylar imaging, custom laser cutting, electroforming, and chemical etching. At Thin Metal Parts, we pride ourselves not only on custom manufacturing but also on superior customer service. Clients working with Thin Metal Parts can expect unmatched responsiveness, quick turnaround times, cost-effective options, with highly flexible and easily customizable manufacturing across prototype, small run, and large volume production.

For more information on the UV laser capabilities contact us.

Request Samples

Using three different technologies, custom metal parts can be built for thousands of applications for a large variety of industries. By combining multiple technology options, a hybrid precision part, unavailable anywhere else in the global marketplace, can be custom manufactured.

Thin Metal Parts regularly works with the aerospace, computer, and electronic industries to build custom precision parts used in industrial and consumer goods applications... parts such as metal encoder wheels, metal mesh, and print heads. In addition, custom parts are developed daily in research and development as the design/process engineer group teams with customers to develop prototypes and production items in medical, manufacturing, and scientific instrument sectors.

All products are custom manufactured to meet customer needs and specifications, including DFARS and RoHS compliance. These quick-turn, cost-effective, low tooling cost processes offer excellent production alternatives to traditional fabrication methods for metal parts in high volumes and prototyping.

Request samples

4733 Centennial Blvd.

Colorado Springs, CO 80919

Phone: 719.268.8300

Fax: 719.268.8399

E-mail: info@thinmetalparts.com